Plant Modeling Services

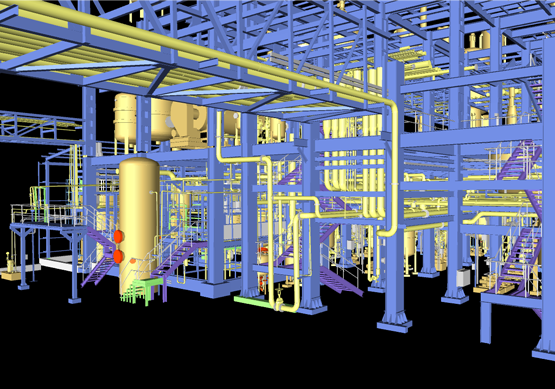

Our Plant Modeling solutions provide accurate, intelligent, and data-rich 3D models of industrial plants, refineries, and processing facilities. Using advanced 3D laser scanning, BIM, and CAD technologies, we capture real-world conditions and transform them into precise digital models. These models support design, engineering, operation, and maintenance throughout the plant lifecycle.

Our Plant Modeling Capabilities:

3D As-Built Modeling – Create highly accurate digital representations of existing plants and equipment.

Piping & Structural Modeling – Develop detailed models of piping systems, structures, tanks, and equipment for design, retrofit, or expansion projects.

Intelligent Data Integration – Embed asset information, specifications, and metadata directly into the model for smarter facility management.

Clash Detection & Validation – Identify and resolve design conflicts between equipment, piping, and structures before implementation.

Simulation & Visualization – Use 3D models for walk-throughs, safety planning, training, and operational visualization.

Scan-to-Model Conversion – Transform point cloud data into intelligent CAD/BIM models for seamless engineering workflows.

Key Benefits:

Accuracy & Reliability – Models reflect real site conditions with millimeter precision.

Enhanced Safety – 3D visualization improves risk assessment and safe planning in hazardous environments.

Cost & Time Savings – Minimize rework and downtime by validating designs before construction.

Better Collaboration – Digital models improve coordination across engineering, procurement, and construction teams.

Lifecycle Management – Supports plant operation, maintenance, and future expansion with reliable digital assets.