Reverse Engineering & 3D Scanning Training

What is Reverse Engineering?

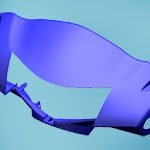

Reverse Engineering is the process of capturing physical objects and converting them into 3D digital models for design, analysis, or manufacturing. It is widely used in automotive, aerospace, medical, consumer products, tool & die, and heritage restoration.

When combined with 3D Scanning technology, engineers can accurately capture complex geometries of parts and turn them into CAD models for redesign, quality inspection, or rapid manufacturing.

Why Learn Reverse Engineering & 3D Scanning?

-

- Companies need digital data of legacy parts that don’t have CAD drawings.

- Saves time in product development & prototyping.

- Used in product improvement, quality control, R&D, and competitor analysis.

- Bridges the gap between physical world (object) and digital world (CAD/CAE/CAM).

- Opens career opportunities in automotive, aerospace, robotics, biomedical, and defense industries.

Training Modules

🔹 Introduction to Reverse Engineering

-

- Understanding fundamentals of reverse engineering.

- Applications in product design, manufacturing, and R&D.

- Reverse engineering workflow – Scanning → Point Cloud → Mesh → Surface → CAD Model → Validation.

🔹 3D Scanning Technology

-

- Types of 3D Scanners:

-

- Contact CMM (Coordinate Measuring Machine)

- Non-contact (Laser Scanners, Structured Light Scanners, Photogrammetry)

-

- Scanning setup, calibration, and accuracy considerations.

- Capturing point cloud & polygonal mesh data.

- Types of 3D Scanners:

🔹 Data Processing

-

- Cleaning and refining scan data.

- Mesh generation and editing.

- Aligning scanned parts with coordinate systems.

🔹 Surface Reconstruction

-

- Converting mesh to NURBS surfaces.

- Creating parametric CAD models from scanned data.

- Software used: Geomagic Design X, PolyWorks, CATIA, NX, SolidWorks Reverse Engineering add-ons.

🔹 Validation & Quality Inspection

-

- Comparing scan data to CAD model.

- Deviation analysis & GD&T checks.

- Generating inspection reports.

🔹 Integration with Manufacturing

-

- Using reverse-engineered data for CNC machining.

- Preparing files for 3D Printing (Additive Manufacturing).

- Case studies: automotive spare part redesign, aerospace tooling, medical implants.

Software & Tools Covered

-

- Geomagic Design X

- PolyWorks

- CATIA / NX / SolidWorks Reverse Engineering modules

- Metrology software for inspection & validation

Concept Design

We can take your ideas / vision and sketch-out and develop preliminary products based on those concepts.

What is Concept Design?

Concept engineering is the process of translating

customer needs to design features and measurable

performance parameters.

Old Concept

We can also say: Define shape first & size later.

Following is the example for concept design to explaining whole process, how imagination (shape) from customer is translated to Parametric Design to emerge Actual Product.

New Concept

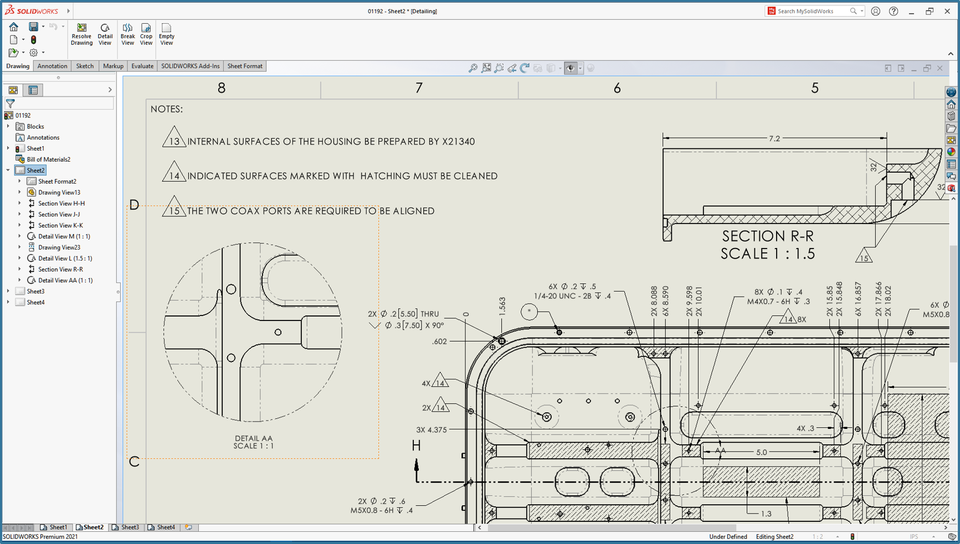

Drawing Detailing Mode Improvements

- Improved performance of Detailing Mode to speed up drawing creation even more

- Improvements in ability to add hole callouts, edit existing dimensions and annotations, and add Detail, Break and Crop views

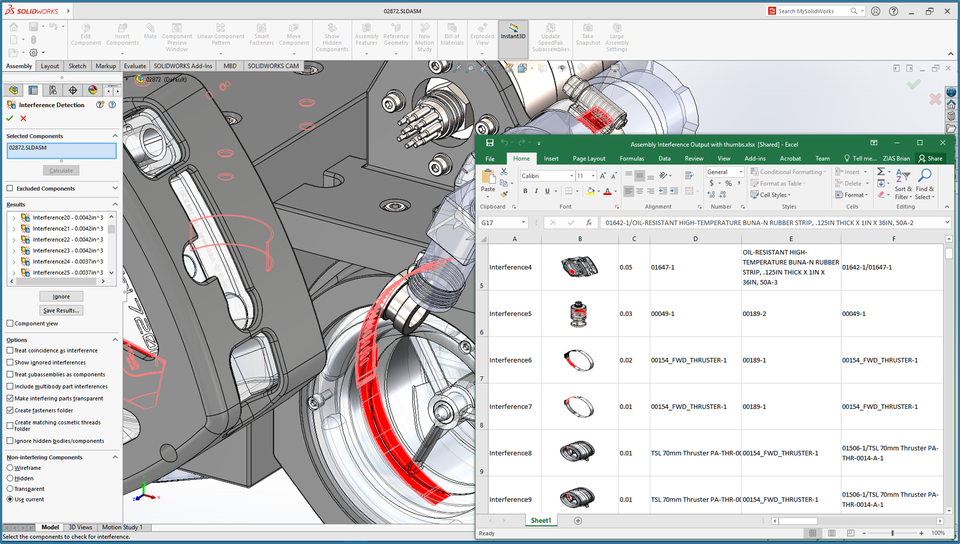

Assembly Modeling Enhancements

- Interference-detection reports exported with images to Microsoft® Excel spreadsheet

- Option to automatically resolve lightweight components upon expanding Feature Tree node

- Chain pattern along path to use curve length, not chord length