Computer-Aided Manufacturing (CAM)

Streamlined Manufacturing with Solid Edge CAM Solutions

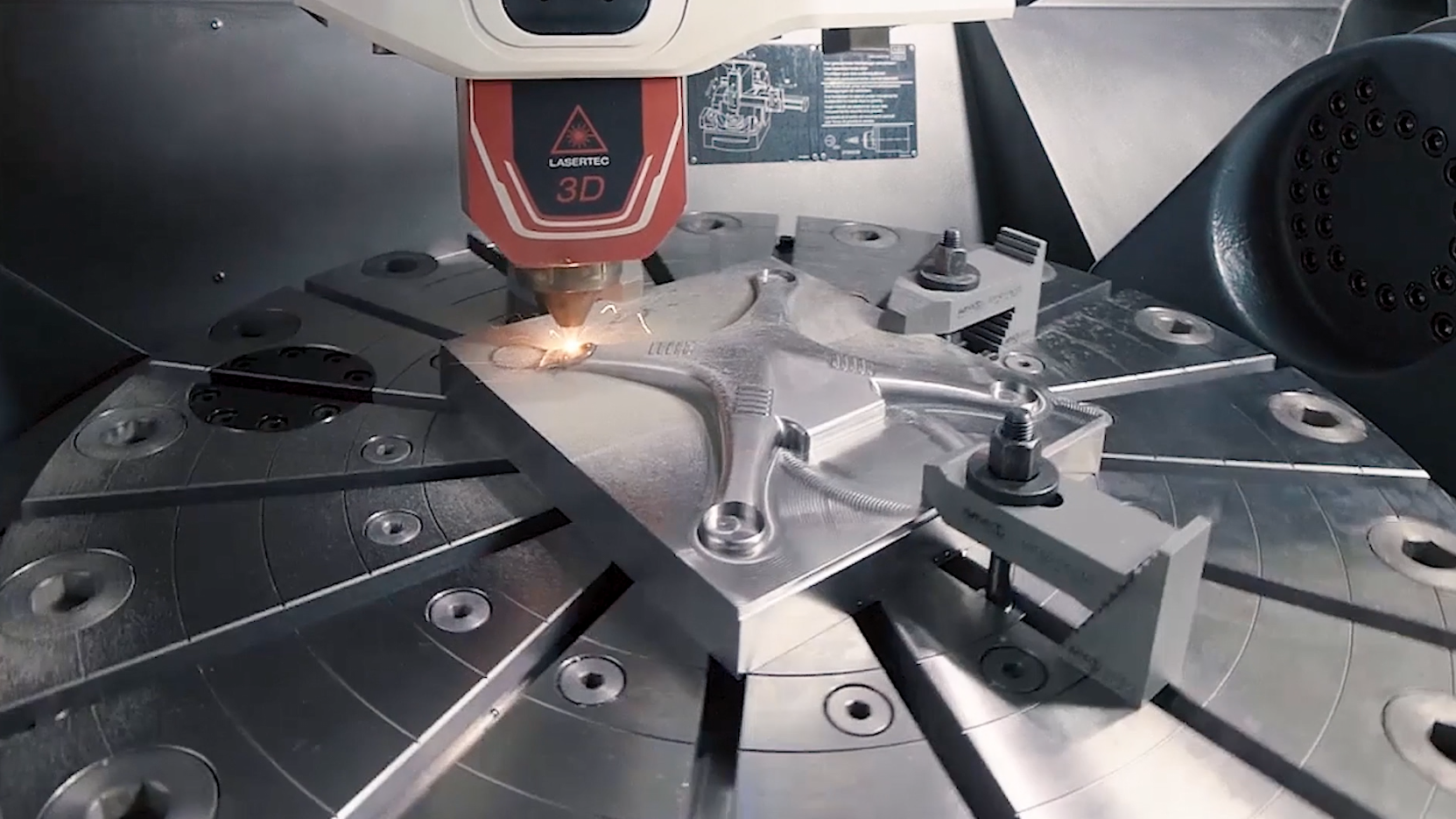

Solid Edge computer-aided manufacturing (CAM) solutions help manufacturers produce world-class products using a wide range of manufacturing processes. Whether you are working with CNC machining, nesting, cutting, bending, molding, welding, assembling, or additive manufacturing, Solid Edge provides the tools needed to ensure efficiency, accuracy, and cost savings.

Why Solid Edge CAM?

Manufacturing companies today face increasing pressure to improve quality, reduce costs, and accelerate time-to-market. With Solid Edge CAM:

- Automate complex manufacturing tasks with intelligent machining strategies.

- Reduce errors and scrap with precise toolpath generation.

- Seamlessly integrate design and manufacturing, ensuring data consistency.

- Support for hybrid manufacturing, combining subtractive and additive processes.

Capabilities

Solid Edge CAM solutions provide powerful capabilities to meet diverse production requirements:

- CNC Machining – Advanced 2.5-axis to 5-axis milling and turning operations for precision manufacturing.

- Sheet Metal Fabrication – Nesting, cutting, and bending automation to reduce material waste.

- Tooling and Molding – Efficient design-to-production workflows for plastic, casting, and die manufacturing.

- Welding and Assembly – Integrated support for welded structures and assembly operations.

- Additive Manufacturing (3D Printing) – Prepare and optimize designs for industrial 3D printing.

Benefits to Manufacturers

- Faster production cycles with automated toolpaths and optimized workflows.

- Improved product quality through accurate digital simulations and machining validation.

- Lower manufacturing costs by minimizing rework, scrap, and material waste.

- Scalability from small workshops to enterprise-level production systems.

Integration with Product Development

Solid Edge CAM is fully integrated with Solid Edge design tools, enabling a seamless digital thread from design to manufacturing. This ensures that engineering changes are reflected instantly in the production process, reducing risks and accelerating delivery.

Related Solutions

- Solid Edge Design for Manufacturing (DFM) – Detect and correct manufacturing issues early in the design phase.

- Solid Edge Simulation – Validate and optimize designs before manufacturing.

- Solid Edge Additive Manufacturing – Integrated tools for preparing parts for 3D printing.