In today’s competitive manufacturing and engineering landscape, precision and accuracy are no longer optional—they are requirements. Whether it’s aerospace, automotive, mechanical components, or medical devices, every product must meet stringent tolerances and international standards. This is where Coordinate Measuring Machine (CMM) measurement and inspection services come into play.

At SunCAD Mechanical, we specialize in delivering reliable CMM inspection services in Australia, ensuring that your components meet the highest quality benchmarks. From 3D dimensional inspection to reverse engineering solutions, our services are tailored to help manufacturers reduce errors, save time, and achieve unmatched accuracy.

What is CMM Measurement & Inspection?

A Coordinate Measuring Machine (CMM) is an advanced inspection tool used to measure the geometry of physical objects by sensing discrete points on the surface. The machine uses a probe system—touch trigger, laser, or optical—to capture dimensions with extreme precision.

CMM measurement services are essential for:

- Ensuring parts conform to CAD models.

- Identifying manufacturing defects.

- Validating prototypes and first article inspections (FAI).

- Maintaining ISO, AS, and ASTM quality standards.

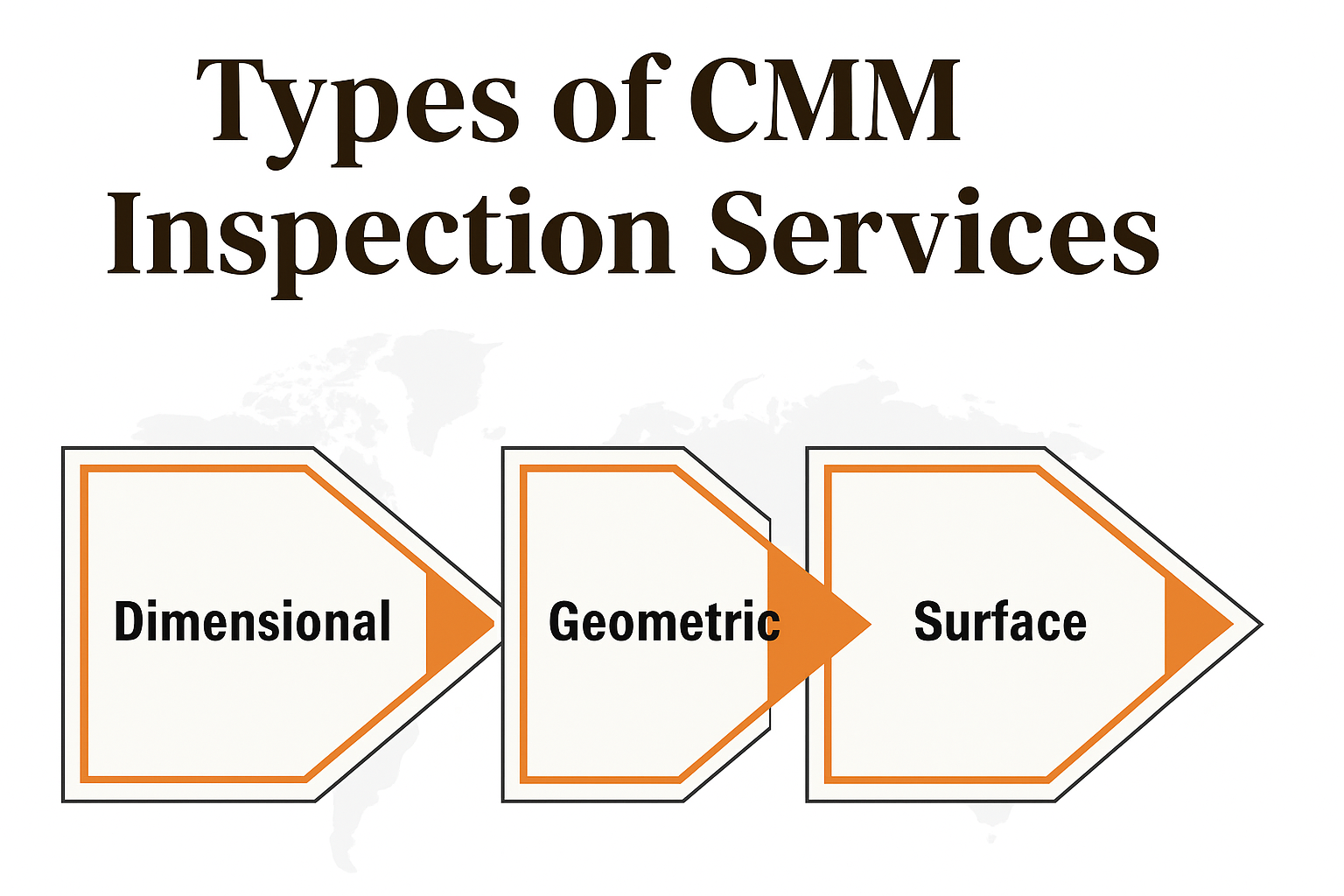

Why Manufacturers Trust CMM Technology

- High Accuracy: Measures tolerances up to microns.

- Time-Saving: Faster than traditional measurement methods.

- Versatility: Works for small components to large assemblies.

- 3D Capability: Captures complex geometries with precision.

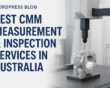

Types of CMM Inspection Services

1. Dimensional Inspection

Dimensional inspection ensures every feature of your component matches the required specifications. Using CMM, SunCAD Mechanical verifies linear dimensions, angular dimensions, flatness, roundness, and true position.

2. 3D Measurement Services

Modern industries rely heavily on 3D models. Our CMM services provide 3D scanning and point cloud data, enabling engineers to compare actual measurements against CAD drawings.

3. First Article Inspection (FAI)

Before mass production, a first article inspection confirms that your prototype meets design intent. CMM plays a critical role in reducing errors before full-scale manufacturing.

4. Reverse Engineering Services

By scanning existing parts, we recreate accurate CAD models for redesign, quality verification, or reproduction. This is widely used in obsolete parts replacement and product improvement.

5. Assembly Verification

CMM also ensures fit and alignment of assembled components, reducing rework costs and guaranteeing seamless integration.

Industries Benefiting from CMM Measurement

- Aerospace & Defence – Precision parts for safety-critical components.

- Automotive – Engine parts, gears, transmission systems.

- Medical Devices – Surgical instruments, implants, prosthetics.

- Oil & Gas – Valves, pumps, pipeline fittings.

- Heavy Engineering – Large-scale machinery and fabrication units.

- Electronics – Micro-components with micron-level tolerances.

Why Choose SunCAD Mechanical for CMM Inspection Services?

1. Advanced Technology

We use state-of-the-art CMM machines and laser scanners capable of measuring both small and large parts with high accuracy.

2. Skilled Engineers

Our team consists of highly experienced metrology experts and CAD/CAM professionals who ensure accurate and reliable results.

3. Customized Solutions

Every project is unique. We provide tailored inspection reports and certificates of compliance based on client requirements.

4. Fast Turnaround

Time is critical in manufacturing. With advanced CMM setups, we deliver quick inspection services without compromising quality.

5. Competitive Pricing

We aim to provide world-class inspection services in Australia at affordable rates, making precision accessible to all manufacturers.

The Process of CMM Inspection

- Component Setup: The part is carefully mounted on the CMM platform.

- Probing & Scanning: Using touch or laser probes, measurements are captured.

- Data Comparison: Actual measurements are compared against CAD models.

- Report Generation: A comprehensive inspection report is generated, highlighting deviations.

- Quality Approval: Clients receive certified results for production validation.

Benefits of Outsourcing CMM Services

- Eliminates the cost of owning & maintaining expensive CMM machines.

- Access to experienced engineers and advanced software.

- Reduces in-house inspection errors.

- Faster approval for production batches.

- Ensures compliance with ISO 9001, AS9100, and other global standards.

Frequently Asked Questions (FAQs)

Q1: What is the accuracy of a CMM machine?

A CMM can measure within microns, ensuring unmatched precision compared to manual inspection tools.

Q2: Can CMM measure large parts?

Yes, with advanced bridge-type and gantry CMMs, we can inspect both small and large-scale components.

Q3: Is CMM inspection required for ISO certification?

Yes, many industries use CMM inspection reports as part of their ISO and AS compliance documentation.

Q4: Do you provide reverse engineering with CMM?

Absolutely. We provide CAD models from scanned data for product re-design and development.

Conclusion

The future of manufacturing lies in precision, quality, and innovation—and CMM inspection plays a critical role in achieving these goals. At SunCAD Mechanical, we are proud to be a trusted partner for businesses across Australia, providing CMM measurement, 3D inspection, reverse engineering, and quality assurance services.