CNC Machine Laser Calibration & Operating Services

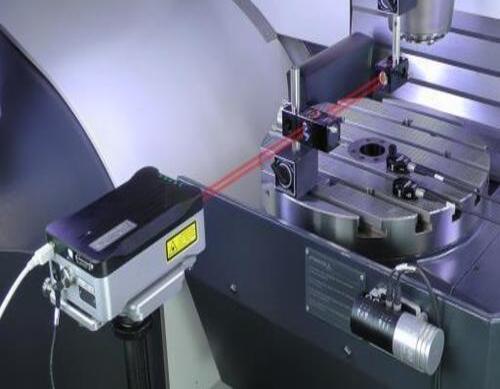

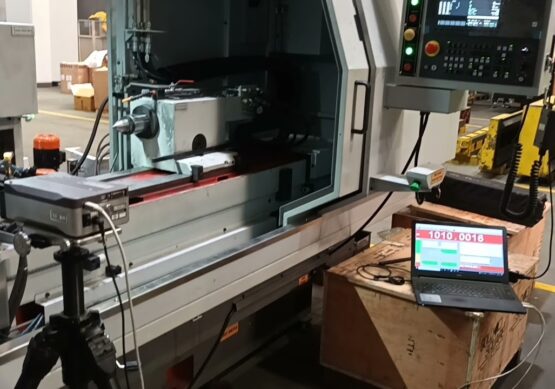

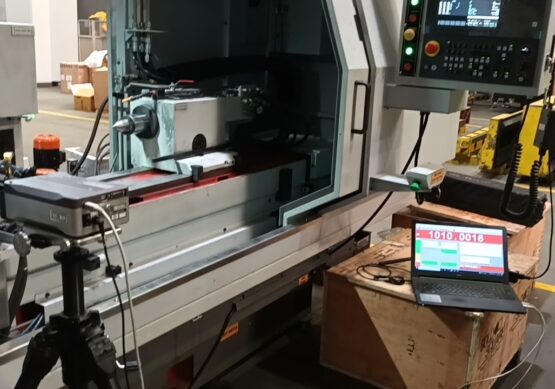

Our CNC Machine Laser Calibration & Operating Services ensure that your CNC machines perform with maximum accuracy, efficiency, and reliability. Using advanced laser interferometry technology, we measure and correct machine errors to maintain the highest precision standards required for manufacturing and machining operations.

Our Capabilities:

Laser Calibration of CNC Machines – Detect and correct errors in positioning, straightness, angular alignment, and spindle accuracy.

Machine Accuracy Verification – Validate machine performance against international standards (ISO/VDI/ASME).

Preventive Maintenance Support – Identify deviations early to reduce downtime and extend machine lifespan.

Dynamic Performance Testing – Analyze real-time machine behavior under operating conditions.

CNC Machine Operation Service – Skilled operators for setup, programming, and running CNC machines with optimized efficiency.

Documentation & Reporting – Deliver detailed calibration reports for compliance, audits, and quality assurance.

Key Benefits:

High Precision Manufacturing – Ensure consistent product quality with sub-micron accuracy.

Reduced Downtime – Prevent breakdowns and avoid costly rework through proactive calibration.

Extended Machine Life – Maintain your CNC machines in peak condition for long-term reliability.

Standards Compliance – Meet global quality and accuracy standards across industries.

Cost Efficiency – Optimize production processes, saving time and resources.

✨ With our CNC Machine Laser Calibration & Operating Services, you can achieve greater precision, improved productivity, and long-term reliability in your machining operations.