NX CAD/CAM Training – From Design to Manufacturing Excellence

What is NX CAD/CAM?

NX (Siemens NX) is one of the most advanced and integrated CAD/CAM/CAE software suites in the world. It is widely used across industries such as automotive, aerospace, heavy machinery, energy, and consumer products for high-precision design, engineering, and manufacturing.

- NX CAD (Computer-Aided Design) – Focuses on creating 3D product designs, assemblies, sheet metal parts, molds, and drafting documentation.

- NX CAM (Computer-Aided Manufacturing) – Enables toolpath generation, CNC programming, milling, turning, drilling, and machining simulations for efficient manufacturing.

By learning NX CAD/CAM, engineers and designers gain the ability to design, simulate, and manufacture products seamlessly within one platform.

Training Modules

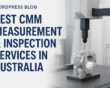

🔹 NX CAD (Design)

- Part Modeling: 3D modeling of mechanical components with parametric features.

- Assembly Design: Creating assemblies, checking motion, and analyzing fit & clearance.

- Sheet Metal Design: Designing sheet metal parts with bends, flanges, cutouts, and forming features.

- Drafting & Detailing: 2D drawings with GD&T (Geometric Dimensioning & Tolerancing).

- Surface Modeling: Freeform surface creation for complex designs (aerospace/automotive).

- Mold & Die Design: Tools for injection molding and die-casting industries.

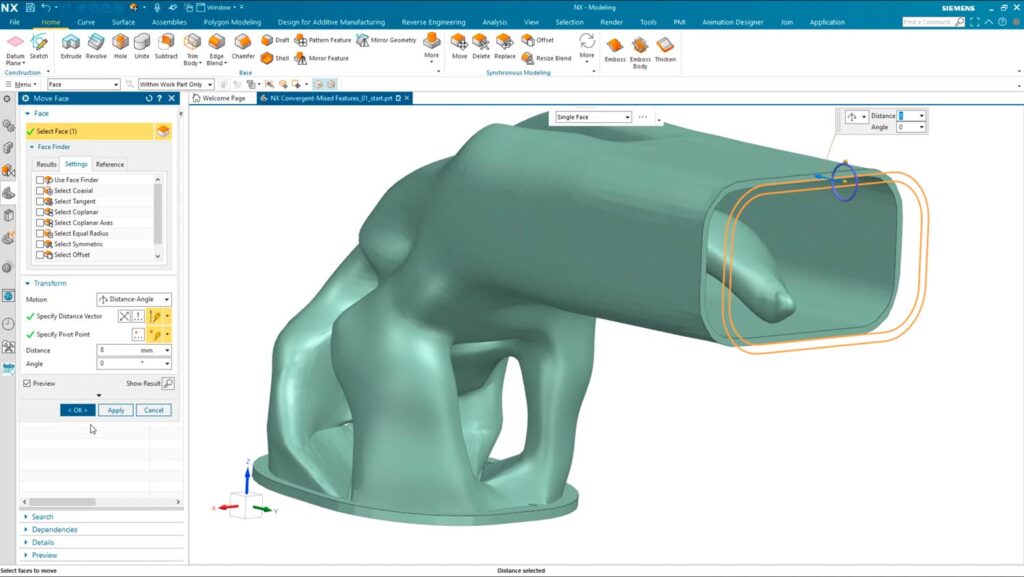

🔹 NX CAM (Manufacturing)

- CNC Programming: Toolpath generation for turning, milling, drilling, and multi-axis machining.

- 2-Axis & 3-Axis Machining: Essential milling operations.

- 5-Axis Machining: Advanced toolpath generation for aerospace/complex components.

- Turning & Mill-Turn: NC programming for lathes and multi-tasking machines.

- Drilling & Hole-Making Cycles: Automated drilling operations.

- Tool Library Management: Creating and managing CNC tools.

- Post Processing: Generating NC code for different CNC controllers.

- Machining Simulation: Virtual verification to eliminate errors before actual machining.

Why Learn NX CAD/CAM?

- Industry-Recognized Software – Used by top companies like BMW, Boeing, Rolls-Royce, Tata Motors, and ISRO.

- End-to-End Workflow – Learn to design and manufacture in one integrated platform.

- High-Paying Career Opportunities – NX professionals are in demand for design engineer, manufacturing engineer, CNC programmer, and product development engineer roles.

- Precision Engineering – Used for aerospace-grade accuracy and high-quality product development.

Learning Outcomes

By the end of this course, you will be able to:

✅ Design parts, assemblies, and sheet metal components in NX CAD.

✅ Create 2D drawings with GD&T for manufacturing.

✅ Generate and simulate toolpaths for CNC machines using NX CAM.

✅ Perform machining simulations to reduce errors and save cost.

✅ Export NC code for 2-axis, 3-axis, and 5-axis CNC machines.

✅ Work confidently on industry-standard projects.

Career Opportunities After NX CAD/CAM Training

- Design Engineer

- CNC Programmer

- Manufacturing Engineer

- Mold/Die Designer

- Product Development Engineer

- CAM Analyst

✨ NX CAD/CAM training bridges the gap between design and manufacturing, making you a complete product development professional.